Process: Oak Street x Uncrate

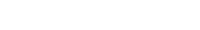

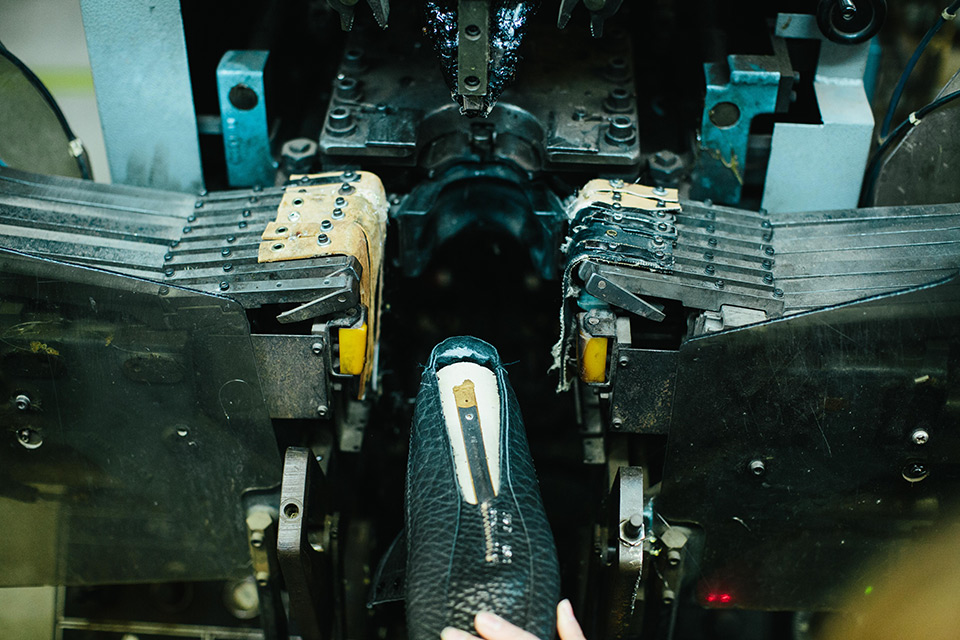

For our new Oak Street x Uncrate Bison Hunt Boots, we spent some long days in Maine, at both the tannery where our bison hides were transformed and the factory where our boots were made. Collected as a byproduct of the bison meat industry, our American shrunken bison leather arrives at the Tasman tannery raw and salted. It's rehydrated, cleaned, and sorted. During the tanning process, Tasman shrinks the grain of the leather using a proprietary formula to enhance the natural beauty of the hides. It's re-tanned with fat liquors and vegetable extracts, and then colored and put through an extensive finishing process. From rawhide to finished leather, it can take up to three weeks. We then delivered the hides to the factory, which is home to fewer than 40 workers. They took the bison leather, and using templates from our friends at Oak Street, crafted 100 pairs of the boots. Each boot passes through the hands of many workers during the process, of which none are sweeter than Rosie, who has stitched more moc toes than she cares to remember.

Photos: Jay Gullion / Uncrate