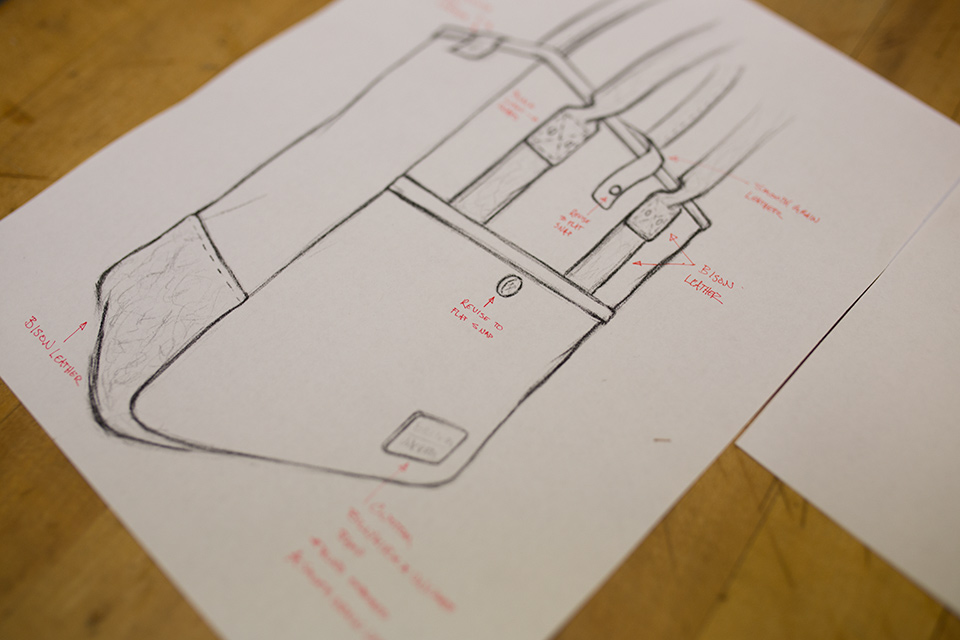

Process: Billykirk

Chris and Kirk Bray of NYC-based Billykirk believe in not only making things in America, but making them right, every time. While putting together each of the three bags found in the Billykirk x Uncrate Stopover Collection, we visited the Bray brothers at their design studio and workshop to get a first-hand look at the collaborative collection being made (by hand, of course), as well as spin a few records and throw a few darts. In a design and manufacturing studio full of sewing, stamping, and clamping machines that could easily be at home in a different era, it's hard not to appreciate the sheer amount of time, detail, and ever-so-hard-to-find craftsmanship that goes in to producing just one Billykirk bag.

Photos: Ray Spears / Uncrate