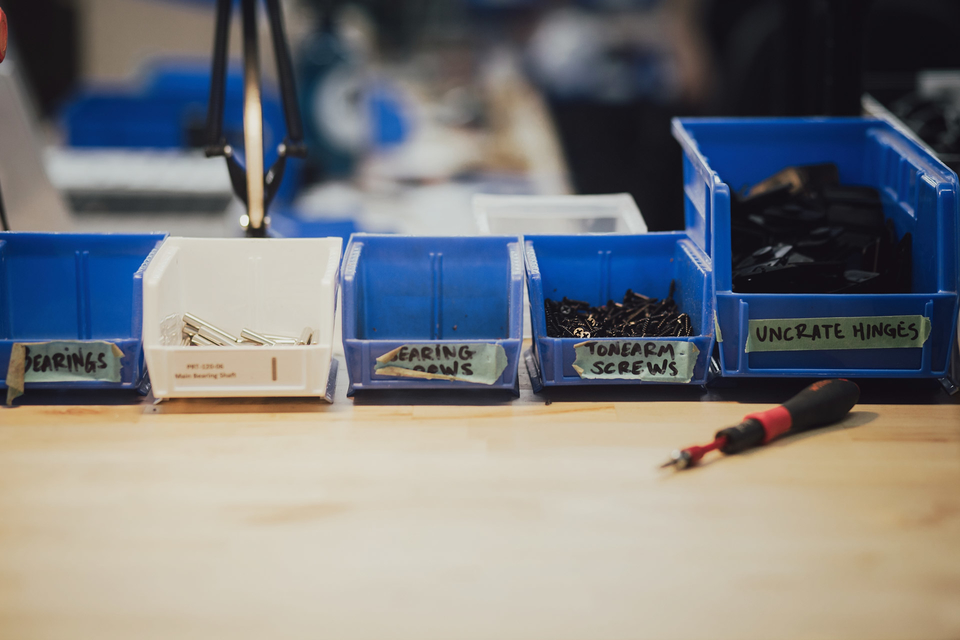

Process: U-Turn

In the town of Woburn, Massachusetts, just a short drive north of Boston, a small team of workers is busy hand-building quality turntables at the headquarters of U-Turn, one of the few American companies building such machines. It all starts with the blank plinth, and the mix of CNC-routing and hand-drilling used to make the holes required for assembly. Elsewhere in the factory, specialized teams work on creating the tonearms, motor assemblies, cue levers, and spindles. Nearly all the components that aren't made in-house are sourced from within the USA. The main assembly line puts all the various pieces together to create a finished whole, while still others work on testing each and every unit before it heads out the door. In all, the company has 20 different stations working at once, a process that allows them to offer 200 unique turntable configurations, and accommodate specialized designs like our just-announced collaboration.

Photos: Ray Spears / Uncrate